Emergency service

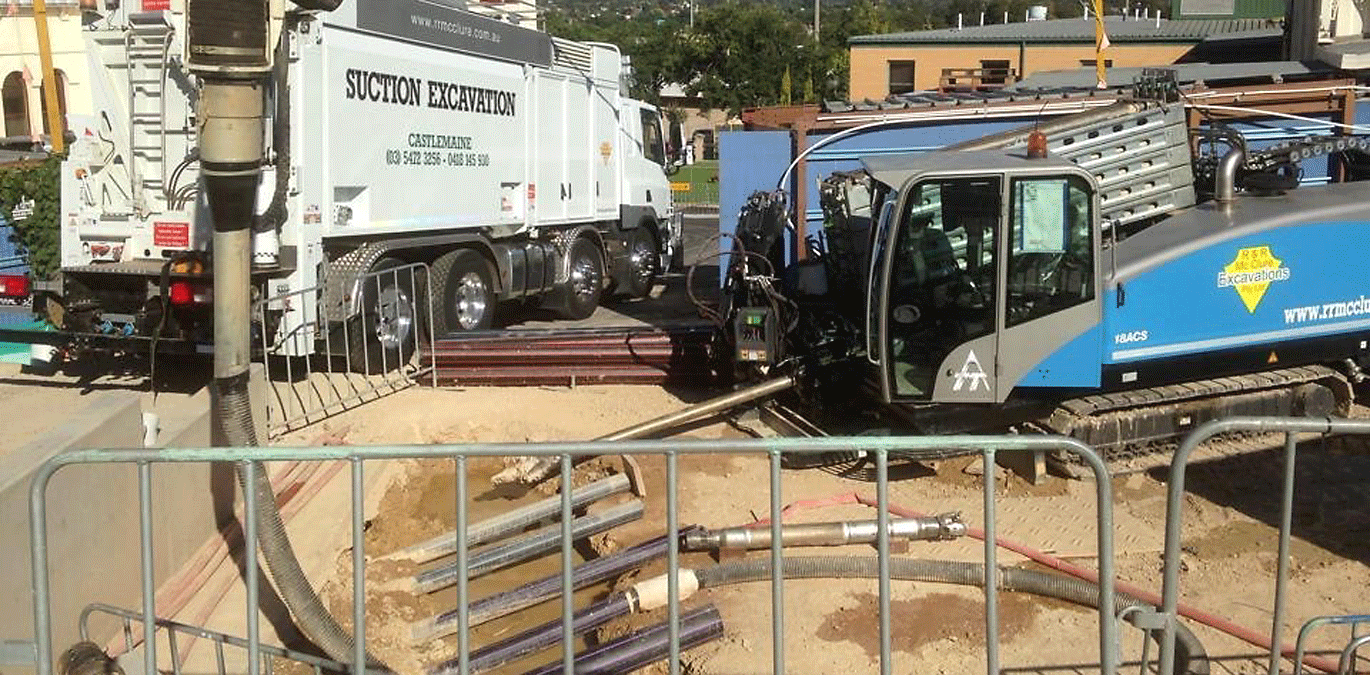

Defective supply cables

The rapid repair of defective supply cables is a major challenge for many network providers. The RSP suction excavator's comprehensive range of equipment in conjunction with a wide variety of accessories enables it to be used quickly and independently. This enables a much faster restoration of the supply.

water

If a pipe bursts, the damaged pipe can be exposed even while the water continues to escape. The strong blast of air guarantees that the escaping water is immediately sucked out, enabling repairs to be carried out without any problems. The use of additional foul water pumps is unnecessary.

Energy and communication

The consequential costs due to damage to the electrical supply system run to several million euros every year. The rapid deployment of an RSP suction excavator minimises the repair time and therefore the consequential costs.

Whether insulation damage or faults in the connecting sleeves, the damaged areas can be very quickly isolated with a suction excavator without causing further damage. The suction air stream itself is no threat to cable systems laid in the ground. Thin electrical or telecommunications cables offer a small surface area to the air and the effect of the force is therefore small, large cables and pipes are protected due to their inherent stability.

Gas

The exposure of damaged gas pipes is extremely hazardous for both people and the environment. However, a potentially explosive gas and ambient air mixture only occurs when the gas content is between 4 and 16%. The high air throughput of suction excavator technology reduces the possibility of the formation of an explosive atmosphere to a minimum, and thus enables work to be carried out safely even with leaking gas pipes. An optional gas warning system continuously checks the gas concentration and further contributes to safety when working.