Comparison of suction excavator vs. vacuum exhauster

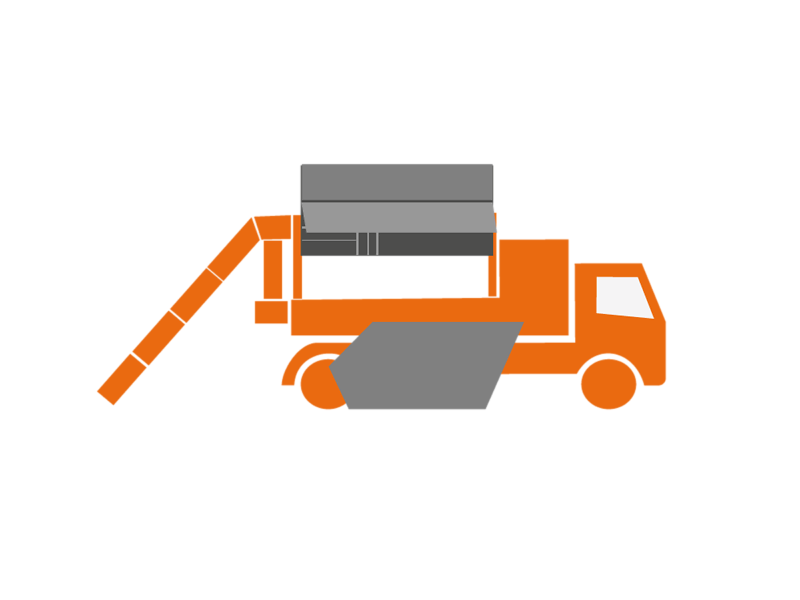

SUCTION EXCAVATOR - A FAN-BASED MULTITALENT

The fan is the main component of the suction excavator. It creates an enormous stream of air which picks up the material. The complex air conveyance system inside the container enable the particles being carried along to be separated. We make use of the law of the gravity for this.

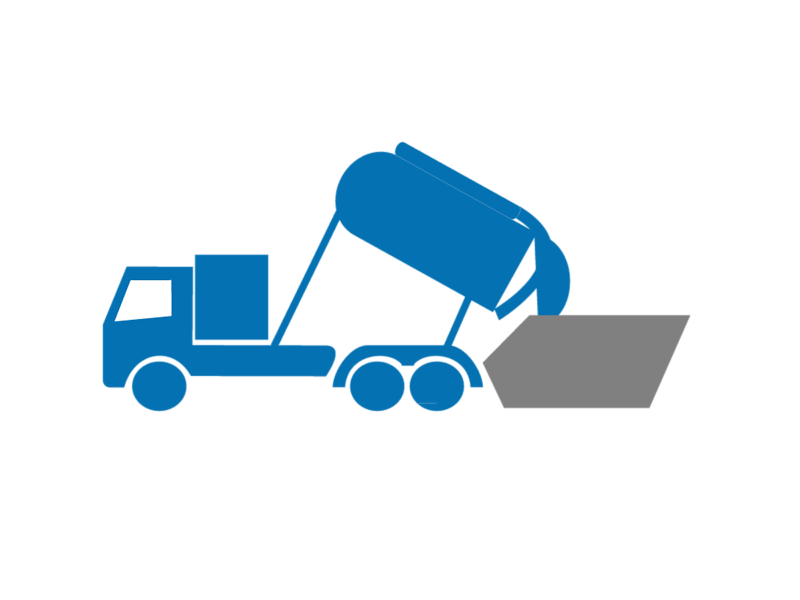

VACUUM EXHAUSTER PUMPS INSTEAD OF SUCTION

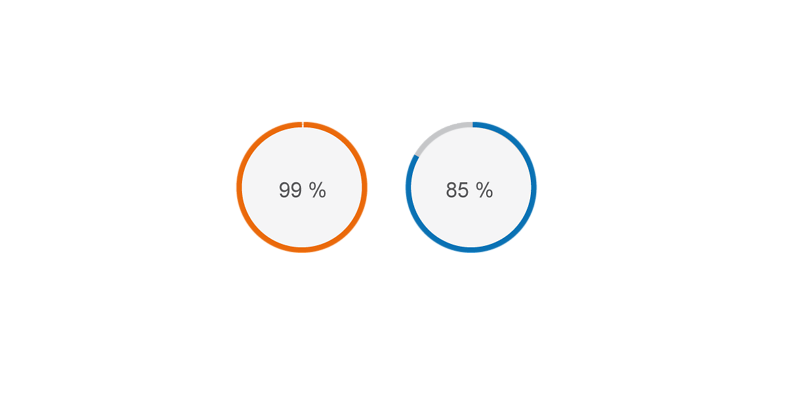

The pump creates the vacuum. Depending on the approach, the material is drawn into the tank or pushed down by the differential pressure of tank and outer environment. The greater or higher the delivery rate of the pump, the less vacuum that can be created, whereby the differences are very small. The smaller pumps create 90 % vacuum and the large ones only 85 %.

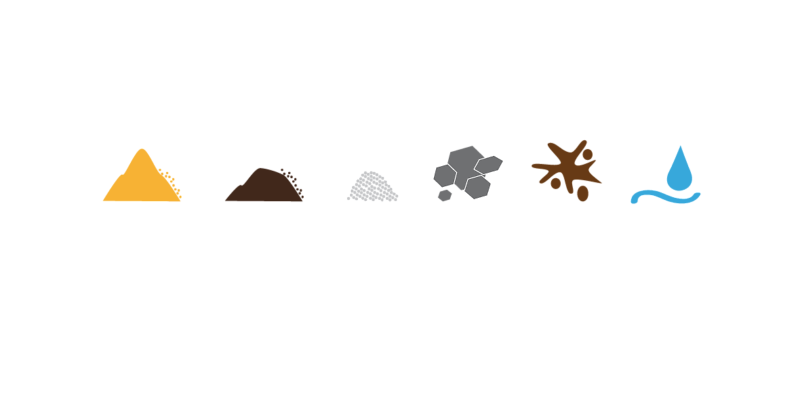

What the suction excavator can suck up...

Suction excavators are mainly suitable for sucking up dry materials, such as sand, earth, gravel and stones. However, mud and water can also be sucked up with a suction excavator. RSP suction excavators are excellently suited to rapid use in the area of underground supply cables but also for cleaning sewage systems and industrial plants.

WHICH MATERIALS DO SUCTION VEHICLES PUMP.

The suction vehicle is used to suck up liquids from normal ducts or pits. However, these vehicles also can suck up materials such as mud or powdered substances. They are rather unsuitable for sucking up materials such as earth, sand, gravel and stones. The capacity of the pump is insufficient for this.

Suction excavators can tip to the left or the right.

Suction excavators have the option of emptying the container to the right or to the left. You can tip the materials into skips, containers or directly on the ground. Sucked up liquids can be drained by means of a pump and drain valve on the co-driver's side.

Vacuum exhausters tip to the rear.

Vacuum exhausters simply pump out liquids. However, it is more difficult to empty solid substances from the tank. To do this, it is necessary to tilt the container very steeply. The required tilt angle is not ideal for filling skips smoothly.

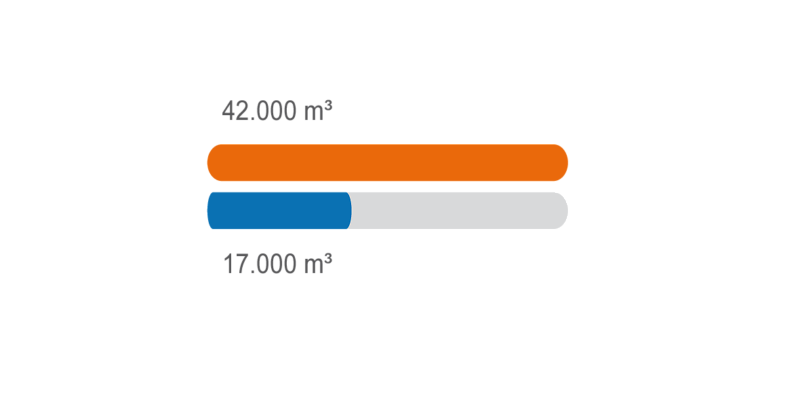

Which volume flow rate is created.

In a direct comparison, the vacuum extractor vehicle and the suction excavator are very different from each other. This can be explained by the two different functional principles. The fan of the suction excavator creates a volume flow rate of 42,000 m³. This high volume flow rate is needed to pick up the material. In contrast to this, the required vacuum for the vacuum exhauster vehicle is the decisive factor required for transporting the material.

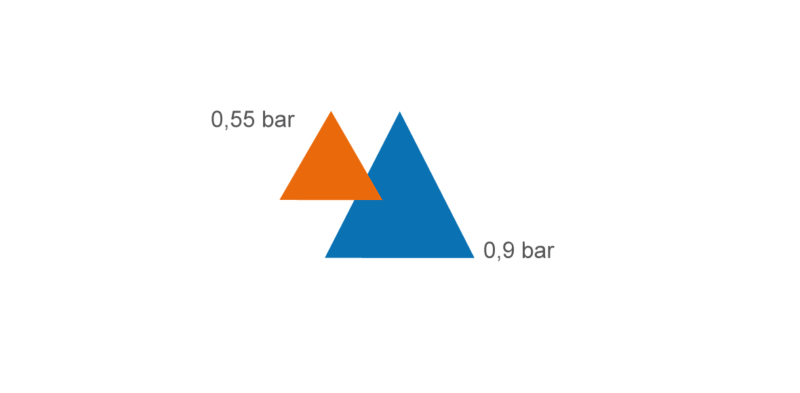

Required vacuum

In order to be able to work efficiently, the suction excavator needs a well-balanced relationship between volume flow rate and the vacuum arising in this process. In vacuum exhausters, the behaviour is exactly the other way round. The pumps create a higher vacuum, however, suction vehicles need a rising volume flow rate the deeper you want to suction.

EFFECTIVE PERFORMANCE

The output created with suction excavators can be used without heavy losses for the suction process. This is different with vacuum exhauster vehicles. The vacuum created with pumps there can be used at most to 85%. Regardless of for which suction vehicle, the possibilities that it offers in use are a decisive factor.

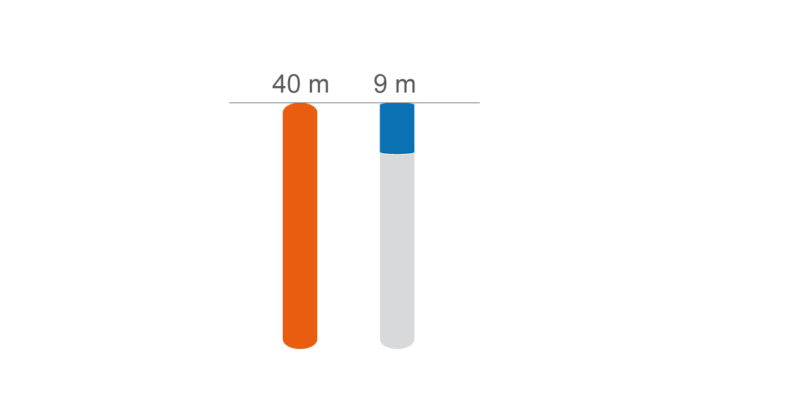

Working deep in the ground

A powerful suction excavator can suck up material from a depth of 40 m. The more deeply one sucks, the more air that must be added applies to vacuum exhauster vehicles. The thicker and the deeper the medium to be suctioned, the thicker the suction hoses must be and the more important the factor of added air becomes. Thick media as well as deep suction work are therefore better carried out using suction excavators.

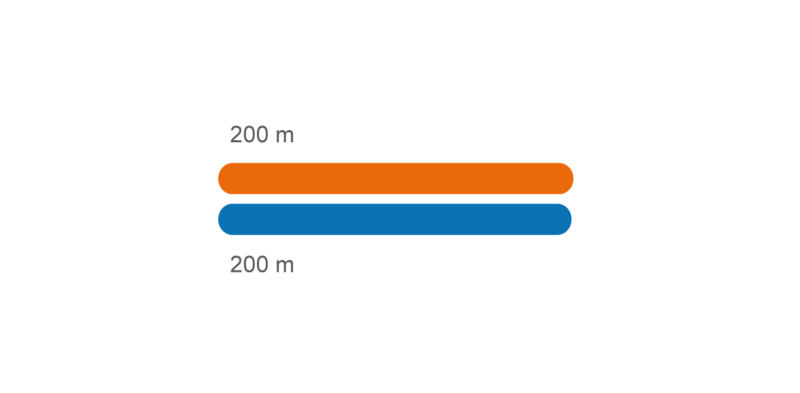

HORIZONTAL DISTANCE

Similarly large distances can be reached with both suction principles when performing suction work over a larger distance in the horizontal. The key variable is the material to be conveyed.

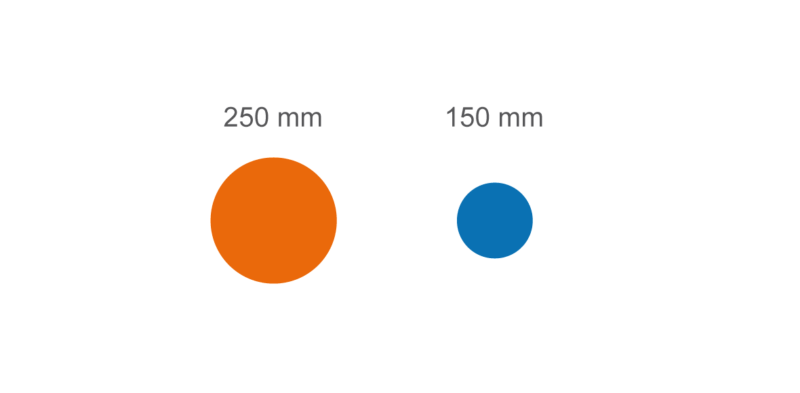

Suction hose diameter

Most suction excavators work with a suction hose diameter of 250 mm. 300 mm diameters were also fitted on request. Only our small entry-level models work with a suction hose diameter of 150 mm like all conventional vacuum exhauster vehicles. Depending on the purpose of the application, both large and small have proven themselves in daily use, however, the 250 mm diameter offers more possibilities for transporting larger suction material.