Technology

Functional principle

Our machines work according to the internationally patented RSP-suction principle. This guarantees maximum gravity separation, very low filter load and therefore constantly high suction capacity. Fuel and therefore money is saved by dispensing with permanent filter cleaning by means of compressed air. We exclusively use high-performance fans that are specially developed for our suction excavators. Independent tests prove that our fans in all classes are among the most powerful ones.

How the suction excavator works

How does a suction excavator work and which modules are necessary for it.

How the suction excavator works.

EquipmentSuction principle

Learn more about the function of the cyclone or ESE suction principle.

Learn more.

patented technology

Patented RSP technology guarantees the highest gravity separation, constant suction capacity at the lowest filter load. Using the thin stream process, all materials up to a diameter of 250 mm can be sucked up.

Learn more.

Modules

The RSP has developed into the market leader of fan-based special suction technology within the last 20 years. Customers from all of Europe, the Middle East, America, Asia and Australia use them successfully. Our extensive range of different basic models in conjunction with a variety of options offers every user the possibility of getting a machine tailored to his needs and requirements.

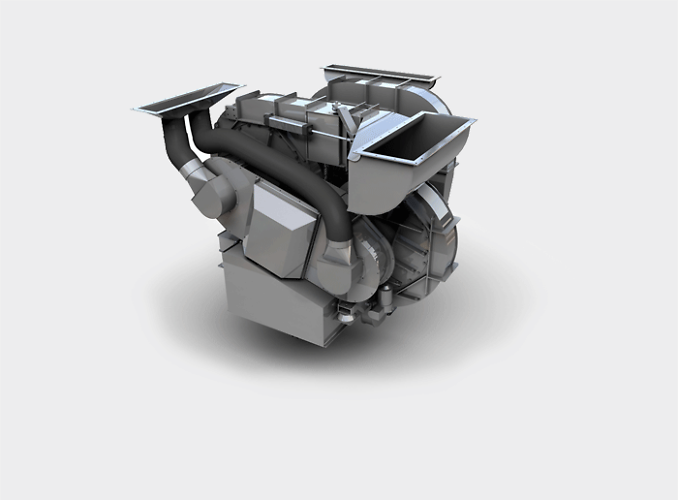

Best suction capacity

The special high-performance fans developed by RSP achieve maximum performance data and the longest service life.

Find out more.

The optimum working range

With the fully hydraulically guided jointed hose carrier, it is possible to work well without extensions at distances between 0 and 6 metres. With a swivel range of 180°, the RSP jointed hose carrier was specially adapted to the site conditions.

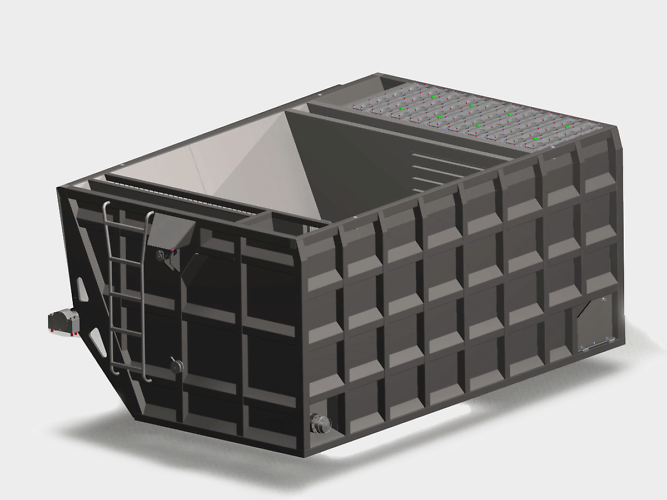

Find out more.The matching container

With four container sizes altogether and the option of equipping these with stainless steel wear plates, there are the perfect conditions for doing a really good job.

Find out more.

RSS simple and safe

The RSP RSS steering system is simply placed on the steering wheel and fixed in place with quick-releases.

It enables safe operation of the optional traction drive using the radio remote control unit.

Safety equipment

Safety equipment is mandatory particularly in large industrial parks. Especially for when working with explosion risks, the machine can optionally be equipped with an earthing and/or gas warning system for our superstructure.

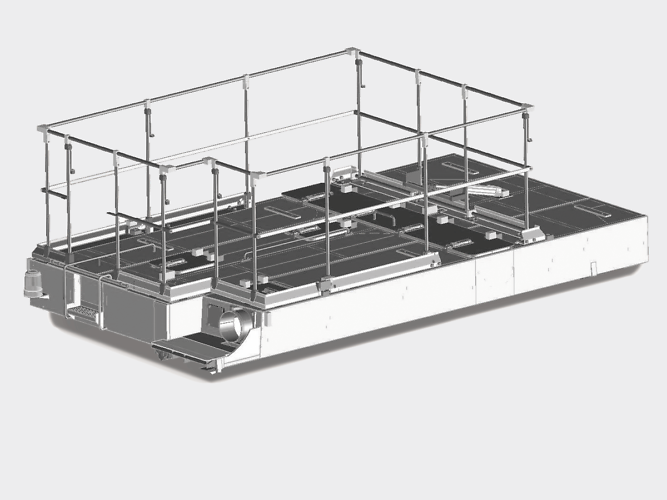

Working safely

The safety rails in two different versions have been specially designed for cleaning and maintenance in the vicinity of the hose inlet and inspection flap.

Find out more.

Earthing with system

For even safer working, particularly in areas where there are stringent safety requirements such as refineries, chemical plants and industrial systems with a risk of explosion. All elements of the superstructure are connected by flexible earth cables.

Find out more.

System with two sensors

For even safer working, particularly in areas where there are stringent safety requirements such as refineries, chemical plants and industrial systems with a risk of explosion.

Find out more.